Innovations in Precision Measurement Technology

Metrology is a common term used in manufacturing to define the study of measurement. Mostly, it means studying measurement within a structure. Everywhere, a manufacturer uses precision measurement technology to form a product.

All the innovations around the use of metrology, which is a high-precision measurement technology. It evaluates parts like car parts to shift naturally. This is why manufacturers inspect and adjust shifts to make a product last long.

Here, you’ll delve into how different innovations incorporate precision measurement technology. Therefore, you’ll understand some of the critical innovations and how you can work to integrate them into your business.

How Metrology Increases Efficiency

Precision technologies assure you increased accuracy, speed, and versatility in dimensional measurement for various industries.

Normally, accuracy is the degree of conformity between the measured value and the actual value of the measured quantity. Precision technology minimizes deviations and errors using accurate reference standards to compare measuring instruments. This will enhance the accuracy of the instrument’s reading. Incorporating precision technologies in different industries has also made processes faster. This is achieved by adding extra features to measuring machines that eliminate typical measuring problems.

The tools phase out manual positioning readjustments and auto-focus lenses and lights to combat temperature changes and ambient vibration. Also, the integration of IoT ensures the measuring systems collect, store, and report data. This speeds up lengthy data organization and time analysis.

Applications of Precision Measurement Technology

Precision measurement is used in a variety of industries, including;

Advancements in Metrology

In technological advancements, Coordinate measuring machines (CMMs) use a high-precision measurement technology probe. It touches the surfaces of a part to collect critical dimension data and then analyzes the information if the product complies with the original CAD dimensions.

Precision measurement technology is also used in 3D scanners to project a light pattern across the part’s surface. During each scan, the patterns change, and the camera records the distortion at different angles, resulting in 3D coordinate measurements.

In an optical measurement system, the high precision measurement technology system is placed on objects like metal parts or car bodies to perform a fast and accurate 3D coordinate measurement.

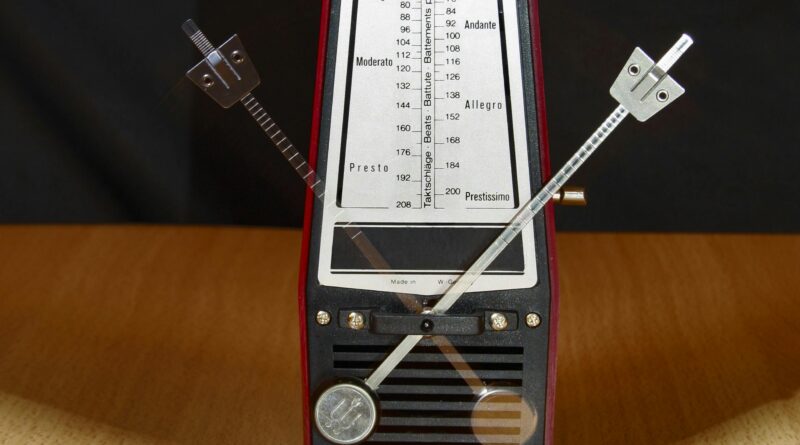

Metrology Equipment

Manufacturing industries use precision technology to achieve standardization and uniformity. In aerospace, high-precision technology in the manufacturing process helps to support manufacturers in developing 3D models instead of fixed tooling structures. The 3D models give engineers a more flexible tool that can be adapted and changed efficiently.

The automotive industry works with highly demanding industrial demands. The high-precision technology enables fast, non-invasive and accurate manufacturing processes. It predicts the function performance of a wide range of vehicle samples. This way, manufacturers can characterize the surface profile, surface finish, and wear volume of different engine parts.

Conclusion

Precision technology is not a science but an essential tool in different manufacturing industries. It gives precision, consistency, and quality. As the world continues to evolve, so will precision technology. So, manufacturers should embrace the advancements to continue producing goods that meet high standards of quality and precision.